Last Updated on December 3, 2025 by UDC Sports

Some mornings on a football field feel exactly like the job promises: cold air, powered-down stadium lights, and a G-max crew unpacking their gear while the surface still holds the chill from the night before. With enough experience, you can walk across the field on that kind of morning and pick up on its condition without trying. The fiber tips tell you how hard the last season was, the infill under your boot shows how well the brushing program kept up, and the base gives away its condition the moment your weight shifts over a spot that’s settled differently than the rest.

After working on replacing enough of these fields—school districts, church programs, the occasional community complex that hosts everything from Friday night football to weekend band festivals—you continually see that fields age in steady, material-driven ways. Fibers lean, backings lose flexibility, seams start asking for attention, and infill behaves according to weather and traffic. And, every one of these synthetic grass sports fields has a point where the fibers, backing, and infill stop performing the way they did on day one.

In the school/community sports field replacement world, that usually shows up between football seasons. An athletic director might mention that the surface feels a little “tired,” or a coach might comment that the ball bounce looks different during warmups.

From a builder’s standpoint, these small signals line up with what the materials are doing underneath.

Artificial Grass Football Field Replacement Cycles

Many football fields in this category replace artificial turf approximately every 8 to 12 years, though this can vary. That range comes from the way the fibers break down under repeated cleat traffic, UV exposure, and infill movement. The field may look fine at a distance, but once the fibers lose enough height and resilience, playability changes and safety testing begins to shift. G-max scores and rotational resistance numbers start wandering upward, and the contractor handling maintenance logs an increasing amount of seam and inlay touch-ups. Those type of trends usually mark the start of replacement planning.

The replacement schedule also depends on how many groups share the field. A small high school football field program playing once a week produces different wear than a campus where football, soccer, band, PE, and community leagues rotate through the lineup all month. More foot traffic equals more abrasion on the fibers and more infill migration, which brings the lifespan closer to the lower end of the range.

Again, as football fields age, most of the wear shows up in predictable ways. Every now and then, though, a field reaches a level of fatigue that goes past the usual signs. It tends to happen when a football program stretches the surface well beyond its intended lifespan or when the infill system hasn’t been maintained for several seasons.

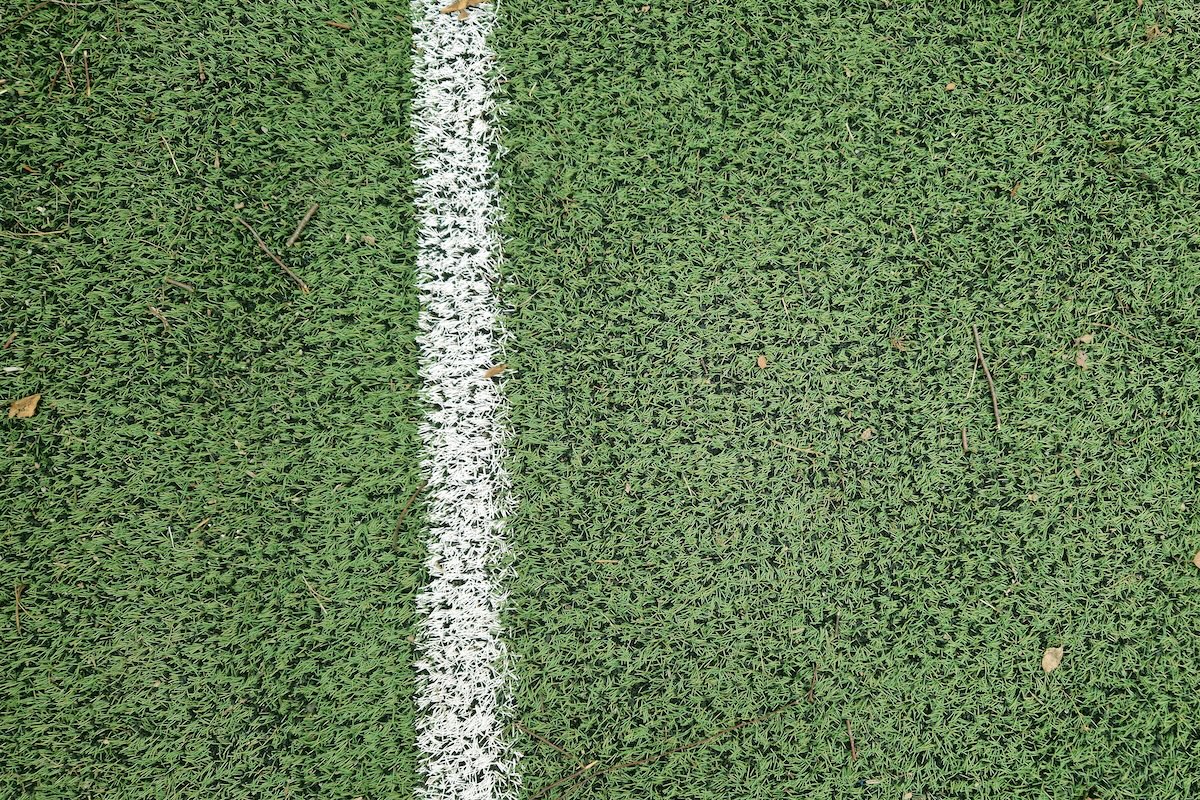

Before talking about football field replacement planning, it helps to look at what that kind of advanced wear actually looks like on the ground. Take a look at the photo below:

The photo above shows a surface that’s moved into that late-stage territory. On the left, the fibers still have enough height to cover the backing. On the right, the infill has been worn down or lost entirely, leaving the tuft rows exposed and the remaining fibers barely hanging on. That level of deterioration isn’t the typical face of an older football field needing regular replacement. It’s the outcome of extended use, infill depletion, or fines working their way into the system until nothing is supporting the pile anymore. When a field reaches this point, the material has given all it can, and replacement becomes the only practical step forward.

How Long the Synthetic Grass on a Football Field Lasts

When you look at the surface up close, the lifespan makes sense. Polyethylene fibers start out upright with good memory. Over time, they split at the tips, bend, and lose their rebound. That process speeds up in high-wear zones like the center of the field, player benches, and the mouth of each end zone.

The backing underneath the fibers ages as well. After nearly a decade of freeze–thaw cycles, UV exposure, and high G-loads during play, the secondary coating becomes less flexible. Once that happens, seams and hash marks begin stretching more under stress. The field is still safe for a while, but the maintenance log gets thicker.

A well-constructed base and reliable drainage layer help the turf last longer when the infill stays evenly distributed. Surface brushing, top-offs, and periodic decompaction delays hardening, which slows down how fast the fibers mat. With consistent upkeep, many community and school football fields can plan to reach 10 seasons without trouble. High usage patterns often shorten that by a couple of years.

Typical Lifespans of Artificial Turf Sports Fields

Across all common-use sports fields — football, soccer, and multi-purpose facilities — the average lifespan lands around the same mark. 8 to 12 years covers the majority. Some facilities stretch toward 13 or 14 seasons when their climate stays mild, usage stays moderate, and the maintenance program targets infill distribution and drainage function.

That said, there are perfectly normal situations where a field needs replacement sooner — and it doesn’t necessarily mean anything was built wrong. It’s often tied to loading, layout, or environmental conditions. A field hitting replacement around 6 or 7 years is still within the normal spread for high-use facilities. It’s mainly when a field fails in the 3–4 year range that contractors start tracing deeper design or construction issues.

Synthetic fields that sit near tree lines or dusty areas can age differently because fines (tiny particles) work into the infill over the years. When enough fines stay in the mix, the infill traps moisture and compacts faster. That makes the field feel firmer and accelerates wear on the fiber tips. All of that feeds into the overall lifespan and replacement planning.

What Affects the Cost of Replacing a Football Field

Replacement pricing swings a lot because a football field is a system, not a single layer. When companies that remove and replace sports fields and contractors estimate replacement, they piece together several moving parts. Each one affects the final cost.

Here are the main variables:

- Extent of removal work: Some fields require only the turf and infill removed. Others need infill separation, disposal steps defined by local rules, or specialized handling when the old carpet contains heavy paint build-up or trapped debris.

- Condition of the stone base: If the drainage profile underneath is stable, the new turf can go right back on top after minor regrading. If deep rutting, contamination, or base migration has occurred, repair work extends the project.

- Chosen turf system: Fiber shape, density, pile height, backing construction, and infill type all influence material cost. Different underlayment pads — if used — add another layer of variance.

- Infill handling and replacement: If the existing infill is in good shape and meets specifications, it can be reclaimed, screened, and reused. If not, full replacement requires new product and extra labor.

- Logistics and field access: Tight sites, limited truck access, or fields surrounded by athletic buildings add time to staging and workflow.

- Off-season scheduling: When a facility has strict windows between football playoffs, graduation setup, and summer camps, crews may need more manpower to compress the timeline.

From the contractor side, it’s generally better to keep the base intact whenever possible because it stabilizes both performance and cost. The base represents a significant portion of the field’s total value over time, and preserving it avoids unnecessary excavation.

How Big-League Venues Handle Turf Replacement

Professional football venues use the same basic turf components—fibers, backing, infill, and drainage—but their replacement cycle operates differently because the workload is intense and highly concentrated.

- Stadium crews refresh or replace turf more often when early-season concerts, preseason schedules, and televised events create heavier wear.

- Testing protocols at these venues run with tight frequency, including G-max, HIC, and fiber-wear mapping.

- Some facilities keep modular turf panels or spare rolls for rapid swaps when sections are damaged.

- Indoor stadiums manage humidity and static with specialized maintenance because the environment affects infill movement.

These operations run at a scale that shortens practical lifespans, which is normal for fields hosting large events, national broadcasts, and high-profile games.

The End Zone

Many school and community fields designed for football land in the same general pattern: 10 seasons give or take, depending on traffic, climate, maintenance, and the day-to-day condition of the base. When fibers start to break down and safety numbers drift, replacement becomes a straightforward decision. Handling the removal cleanly, preserving the base, and selecting a turf system that matches the facility’s workload sets the field up for another long run.